Our Weather Barrier Helps With Concrete Insulation of Your Structure

Comments Off on Our Weather Barrier Helps With Concrete Insulation of Your Structure

At ThermaCote, Inc., we have over three decades of experience developing advanced concrete insulation & protection systems and protective weather barrier coatings. We continually create tailored solutions to help our customers reduce energy gain or loss, protect personnel, and address safety concerns. From chemical attacks to standard erosion, concrete structures experience frequent abuse—without proper protection, they can crack, weatherize, and disintegrate. Our ThermaCote® coating protects concrete substrates from abrasion and corrosion, all while reducing the Urban Heat Island Effect.

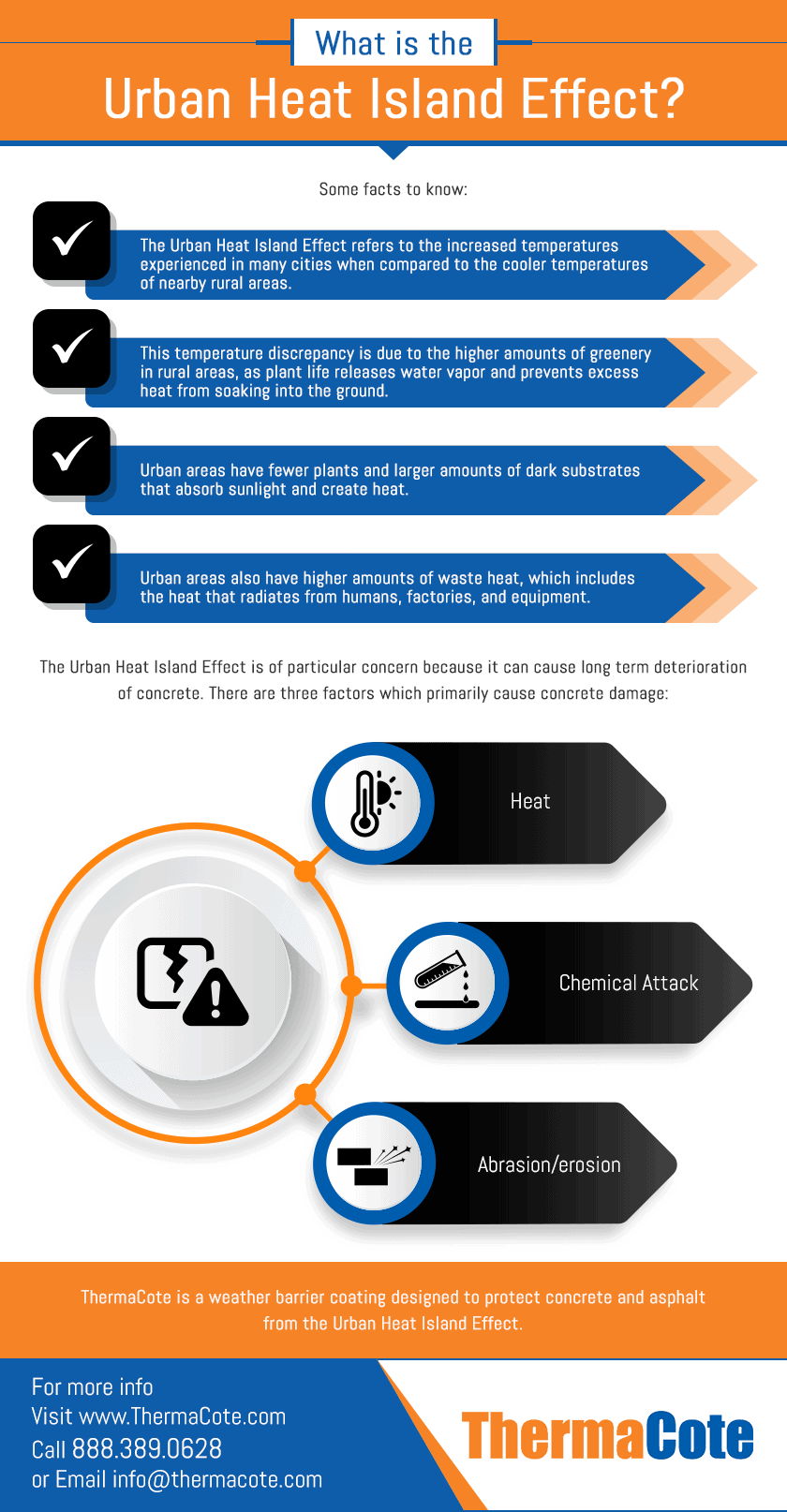

What is the Urban Heat Island Effect?

The Urban Heat Island Effect refers to the increased temperatures experienced in many cities when compared to the cooler temperatures of nearby rural areas. This temperature discrepancy is due to the higher amounts of greenery in rural areas, as plant life releases water vapor and prevents excess heat from soaking into the ground. However, urban areas have fewer plants and larger amounts of dark substrates that absorb sunlight and create heat. Additionally, urban areas have higher amounts of waste heat, which includes the heat that radiates from humans, factories, and equipment.

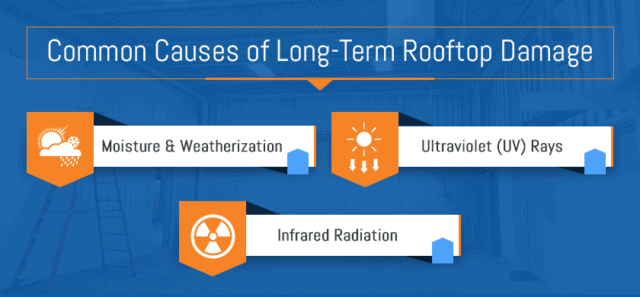

The Urban Heat Island Effect is of particular concern because it can cause long term deterioration of concrete. There are three factors which primarily cause concrete damage:

- Heat

- Chemical attack

- Abrasion/erosion

Heat

Although concrete can generally withstand high temperatures, it is prone to damage from Urban Heat Island Effect. This damage is due in large part to thermal cycling—concrete in areas that experience sudden drops and spikes in temperature can lose its strength more rapidly over time. Additionally, if the concrete contains water that has not previously been allowed to evaporate, high temperatures can cause sudden evaporation, which causes the concrete to spall.

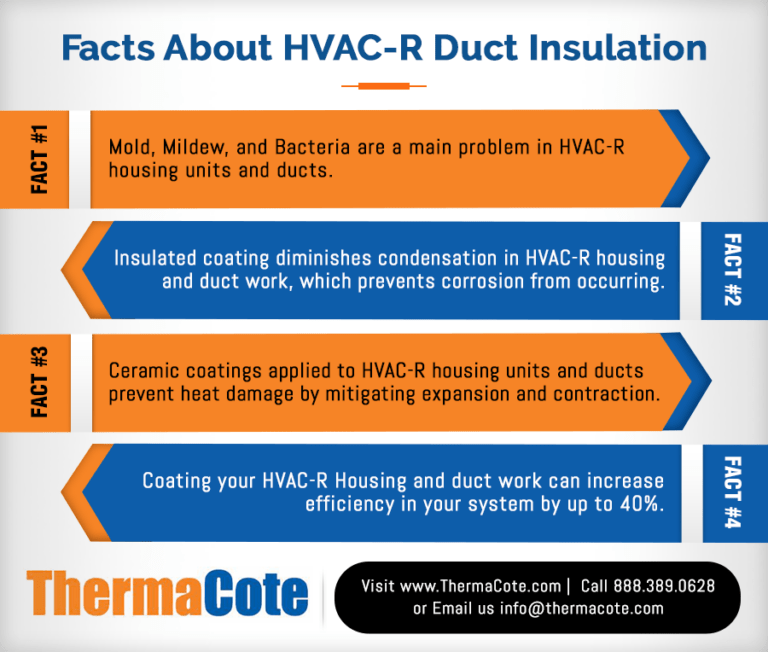

Chemical Attack

Dry chemicals have little impact on concrete, but there are three chemical solutions which can cause damage even to high quality concrete:

- Acids. Concrete may hold up to some weaker acids, but it will generally deteriorate if it encounters any solution that has a pH of three or lower. This type of damage is caused by a chemical reaction between the acid and the cement’s calcium hydroxide.

- Salts and alkalis. Ammonium salts also produce significant amounts of damage in concrete, as they react to the alkaline environment and release hydrogen ions and ammonia gas. Other types of chlorides, such as iron, aluminum, and magnesium, may all cause damage.

- Sulfates. Many types of sulfates, such as calcium, potassium, or sodium, can produce chemical reactions when they come into contact with cement’s hydrated compounds. In high amounts, these sulfates disrupt the cement paste by increasing internal pressure, reducing the strength of the concrete.

Abrasion/Erosion

Concrete structures which frequently experience abrasion will deteriorate over time as the outer concrete paste wears down. This type of erosion is most common in hydraulic structures, including tunnels and spillways. It can also frequently occur on surfaces such as sidewalks and roadways.

Concrete Insulation Using ThermaCote®

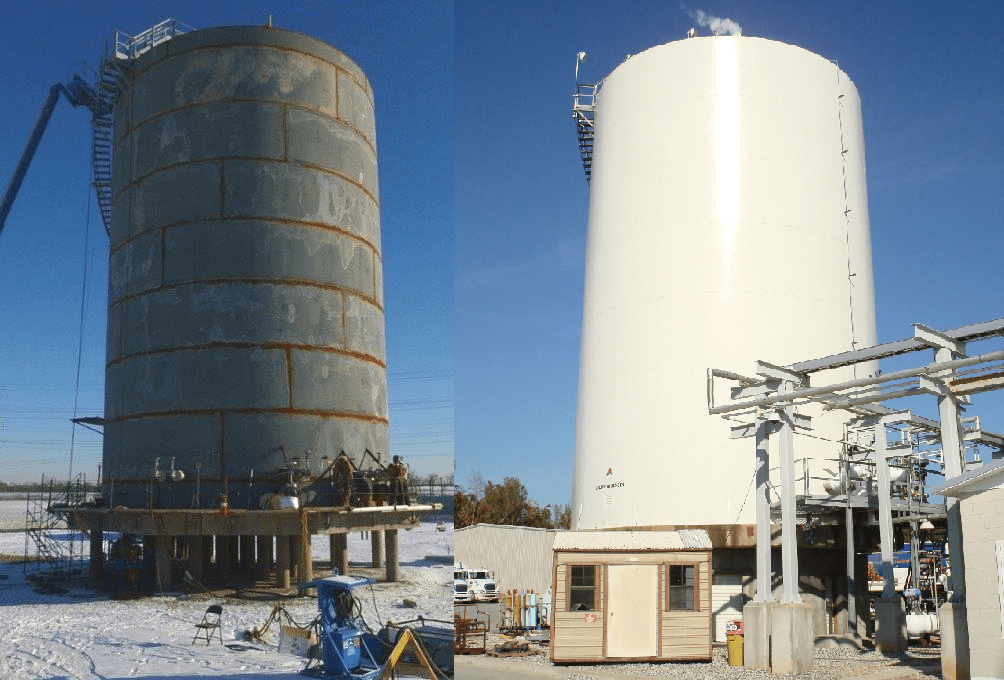

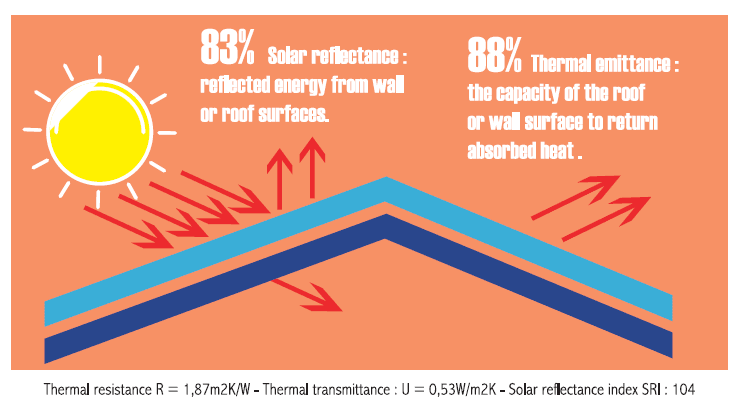

Utilizing a high-quality weather barrier coating such as ThermaCote® can prevent building envelope failures and is particularly advantageous on concrete structures. This environmentally friendly coating improves a structure’s efficiency by reducing heat transfer and preventing weathering and moisture damage.

ThermaCote® significantly increases the substrate’s durability and lifespan. Applying a protective coating reduces the risk of damage, cracking, and discoloration, thus increasing the odds that the concrete will last several decades without the need for replacement. Concrete insulation also protects concrete from UV rays and stains.

ThermaCote® is appropriate for both indoor and outdoor use. Made from ceramic technology, this advanced thermal barrier coating is a highly effective way to reduce the transfer of energy, thus saving money and reducing a structure’s environmental impact. It is MAS Certified Green™ and sustainably produced. Our product has a CE mark for concrete protection, which certifies our product for use with concrete projects of all magnitudes. ThermaCote®, when dried, resembles latex paint and can easily be applied to new projects or used to help retrofitting during construction upgrades.

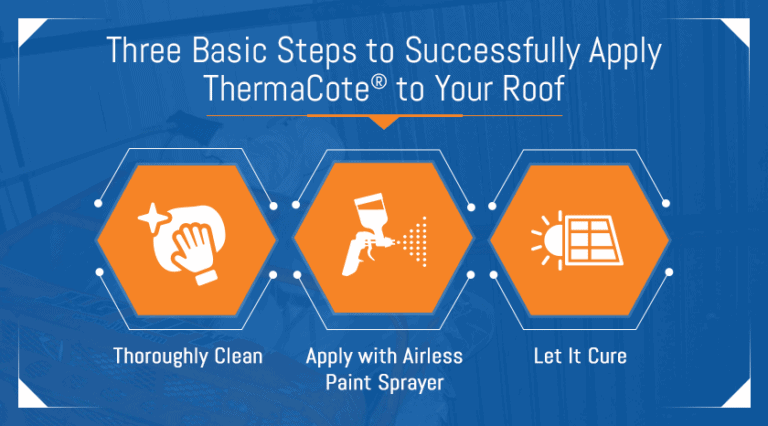

When considering concrete insulation and protection, ThermaCote thermal barrier coating can be easily applied with ceramic spray equipment. Common applications include:

- Concrete slabs for structures

- Roadway columns and overpasses

- Concrete wall coverage

- Roadway bridge structures

- Sidewalks, driveways, and garage surfaces

How Can ThermaCote Help You?

At ThermaCote, Inc., we are dedicated to helping our customers increase their energy efficiency, save money, and prolong the lifespan of their concrete structures—all with no hassle or stress. To learn more about our concrete protection solutions, contact us today.